Avoiding punching shear is essential to the safety and stability of a concrete slab structure. This article delves into the basics of punching shear to demystify the concept.

Author: Rob Gray, Operations Director and Head of Civil and Structural Engineering, London, UK

What is punching shear?

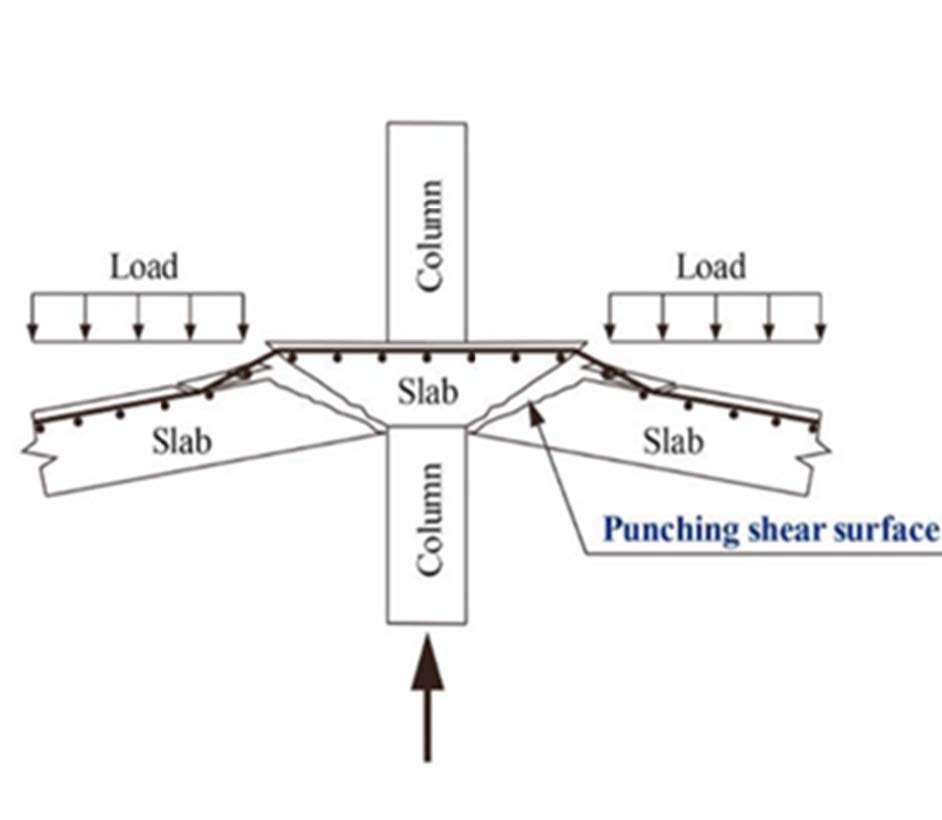

Punching shear occurs in reinforced concrete structures, particularly in slabs or flat plates. When loads, such as the weight of a building and its occupants, act on a slab, it results in a concentrated force which at certain points can result in a unique type of stress known as punching shear, usually around a column. Imagine a pen beneath a sheet of paper. When the paper is pushed down the pen causes a build-up of stress in the paper around the point of contact. It is possible for this pressure to build up to the point that the pen punches through the paper, in the same way as a column might punch through a slab.

The science behind punching shear

Reinforced concrete comprises a combination of concrete and steel reinforcement bars (known as rebars). The concrete provides the compressive strength, while the rebars enhance tensile strength. Together, they create a robust composite material.

In a concrete slab, columns or supporting elements transfer loads to the slab. However, at the connection between the slab and these supporting elements, there is a vulnerability to punching shear. The concentrated force at these points can exceed the slab's capacity to withstand the load, leading to failure. The failure is usually ‘brittle’ in nature, in that it can be sudden and without warning. Brittle failure is to be avoided, as the impending failure is not obvious and therefore capable of fatal consequences.

Punching is one of the least understood forms of structural action in concrete design, and as a result, understanding has been built-up through testing. Code of practice (COP) recommendations have essentially been developed on an empirical basis.

Figure 1. Schematic diagram showing the loads and a potential punching shear failure plane.

All COP guidelines deal with punching shear resistance in the same way, namely determining the stress at a control perimeter around the loaded area (commonly the connection point between the column and slab). The distance from the perimeter to the loaded area varies by COP.

Key factors influencing punching shear

Several factors influence the occurrence of punching shear in a concrete slab. The first is the design of the slab itself – its thickness and the arrangement of reinforcement bars play a pivotal role. Thicker slabs generally have a higher capacity to resist punching shear, while well-placed reinforcement bars can distribute the load more effectively.

The layout of columns and the distance between them also influence punching shear. If columns are too closely spaced, the load on the slab is concentrated in smaller areas, increasing the risk of punching shear. On the other hand, wider column spacing allows for a more even distribution of loads, reducing the likelihood of failure.

Preventing punching shear

Engineers employ various design and construction techniques to prevent or mitigate punching shear in concrete structures. One common approach is the inclusion of shear reinforcement, often in the form of stirrups or inclined bars. These reinforcements act as a safety net, distributing the load across a broader area and preventing the concentrated forces that lead to punching shear.

Figure 2 – This image shows the steel reinforcement for a slab around a column prior to the pouring of concrete. [1] The triangular-shaped bars improve the slab’s resistance to punching shear locally around the column.

Additionally, selecting an appropriate slab thickness based on the intended use of the structure is crucial. Thicker slabs can handle more significant loads, providing a buffer against the risk of punching shear. In some cases drop panels may be appropriate, where the slab is locally thickened around the column.

Engineers also consider factors such as the type of concrete mix and the curing process to enhance the overall strength and durability of the structure.

Real-world examples

Punching shear failure of flat slabs has caused serious accidents in the past. In 1997, Pipers Row car park in Wolverhampton collapsed due to a punching shear failure, exacerbated by deterioration of the concrete slab around the columns. The resulting loss of strength in the concrete made the slabs vulnerable to punching shear.

A more deadly failure occurred in Seoul in 1995, when the Sampoong Department Store collapsed, killing over 500 people. A series of design changes, including removal of columns, construction of smaller columns than the design envisaged, and increased plant loads on the roof, meant the floor slabs became more susceptible to a punching shear failure. Significant reforms to South Korea’s building codes were enacted following the collapse.

More recently, the 2021 Champlain Towers South collapse, in Surfside Florida, also appears to have been partially caused by punching shear failure. Whilst the official investigation into the causes of failure has yet to be completed, poor maintenance, coupled with changes to the loading pattern of a pool deck and limited robustness of the structure have been postulated as potential antecedents to increased vulnerability of the structure to punching shear.

The three examples above have a common theme; the design and construction were (or has been alleged to be) insufficient, through inadequate COPs, design errors or unverified changes to the design. The structural frame was therefore vulnerable to punching shear failure and changes to the building over time, such as deterioration of the structure, in conjunction with inadequate maintenance or changes to loading patterns. This increased its vulnerability, and may have ultimately been behind the collapse.

Conclusion

In essence, punching shear is a phenomenon that demands careful consideration in the design and construction of concrete structures. It is an invisible force that engineers strive to overcome through thoughtful planning and innovative solutions. As we navigate the urban landscape, surrounded by buildings that stand tall, it is worth appreciating the science behind their stability, with the mitigation of punching shear being a key aspect in ensuring they withstand the test of time.

1. "File:Durchstanzbewehrung-Stahlbeton.jpg" by Get the picture is licensed under CC BY-SA 4.0. To view a copy of this license, visit https://creativecommons.org/licenses/by-sa/4.0/?ref=openverse

This article was written for issue 27 of the Diales Digest. To view the publication, please visit: www.diales.com/diales-digest-issue-27