Binu Joseph and Sean Hugo, Senior Consultant and Operations Director - Abu Dhabi, Driver Trett UAE - take a look at the as-planned versus as-built method of delay analysis and assess the applicability of the method for expert testimony.

Introduction

The deposition of expert testimony within the specialist field of forensic delay analysis, can be ad hoc and inconsistent. The acceptance of such evidence, by triers-of-fact, appears on occasions also to be accepted and rejected through experience or instinct rather than the application of a standard test. In recent times Experts have looked to the as-planned versus as-built (APAB) approach when giving expert evidence largely because it is perceived to be factual and pragmatic. This article explores the APAB methodology through an assessment of the prevailing body of knowledge (BOK) and a practical case. The conclusion of which puts forward an opinion of whether the APAB approach conforms to a scientific test or a subjective interpretation which may be subject to heuristic bias (subjective interpretation). Pragmatic is defined as “dealing with things sensibly and realistically in a way that is based on practical rather than theoretical considerations”. Can the APAB methodology be considered as pragmatic and if so, what are the shortcomings of the analysis technique?

Definition Expert Testimony

Before exploring the mechanics of the as-planned versus as-built method of delay analysis, it is sensible to review the way in which the courts typically receive and interpret expert evidence. The Scottish case of Kennedy v Cordia is instructive in this respect where Justices Reed and Hodge provide obiter on expert evidence. Justices Reed and Hodge comment that there are four primary considerations which govern the admissibility of expert evidence (i) “whether the proposed skilled1 evidence will assist the court in its task”, (ii) “whether the witness has the necessary knowledge and experience”, (iii) “whether the witness is impartial in his or her presentation and assessment of the evidence” and (iv) “whether there is a reliable body of knowledge or experience to underpin the experts evidence”. In the author's opinion and experience the first three factors are usually clarified during the cross-examination process. Given the different methods and techniques embodied by the “science” of delay analysis and coupled with the varying levels of practitioner’s expertise, the results of the analysis can be variable but not necessarily incorrect which presents significant challenges for triers-of-fact, ultimately negating any useful assistance to the tribunal or court.

As-Planned v As-Built Methodology

Originally, the SCL Protocol (October 2002)2 has set out the basic methods of delay analysis i.e. Impacted As-planned (IAP), Time Impact Analysis (TIA), as-planned v as-built (APAB) and Collapsed as-built (CAB). Keane and Caletka (2008)3 defined these methods as the four primary methods of delay analysis.

The AACE International Recommended Practice No. 29R-03 titled “Forensic Schedule Analysis” (FSARP)4 further divides these primary methods into a broader grouping of “observational” and “modeled” methods. As the name implies the observational methods involve examining a programme of works by itself or in comparison with another programme. Whereas, in the modeled method of analysis the analyst inserts or extracts activities that model delay events into or from a CPM5 network and then compare the recalculated results of the ‘before’ and ‘after’ states.

While the APAB approach is an observational form of analysis carried out retrospectively, the other three primary methods viz. IAP, TIA and CAB are modeled forms of analyses. The fact that the APAB approach is an observational method makes this method a common-sense and factual based approach as it relies on observing and comparing the actual progress with the original planned intent. This method of analysis does not hypothetically simulate the effect of added or extracted events from the schedule. The analyst draws important conclusions such as the As-Built Critical Path from interpreting the facts at hand using a sound understanding of the construction process and a thorough review of reliable contemporaneous planning records. This is the primary reason, the APAB methodology is a preferred method of analysis when giving expert testimony.

The conclusion sought by the courts is the quantification of excusable, non-excusable, and compensable delays and the function of the delay expert is to establish the causation and quantum of delay to critical and near critical paths.

The SCL protocol (2nd Edition)6 defines the critical path as “the longest sequence of activities through a project network from start to finish, the sum of whose durations determines the overall project duration”. Critical delay is referred to as “a delay to progress of any activity on the critical path…”. ‘Near-critical’ activities are activities with minimal total float values with a high probability of becoming a critical activity.

As stated in the FSARP7, near-critical activities have the greatest potential of becoming concurrent delays. So, the process of evaluating concurrent delays involves identifying critical and near-critical delays. Liability of the delay is a matter for the court/tribunal to decide.

The base of APAB analysis is generally an approved planned programme where the sequence of works and logic links are agreed by the parties involved. The actual progress information (as-built data) is compared against the critical and near critical paths of the planned programme. The review of progress/delays against an approved programme makes the APAB delay analysis contractually reliable. Accordingly, the APAB methodology involves the following steps:

- Assessment and validation of the as-planned critical and near critical paths;

- Identification of the as-built critical path and near critical paths; and

- Establishment of the causation and quantum of delays to critical and near critical paths.

The APAB analysis is straight-forward so long as the as-planned critical path and the as-built critical path are similar. This occurs primarily in works which are sequential in nature such as a tunnelling project. However, in complex construction projects, the as-planned and as-built critical paths are generally never the same. This is because, as the project progresses the activities which were initially critical may fall off the critical path and become non-critical and the near-critical activities may become critical due to the prevailing progress of the works and other external influences.

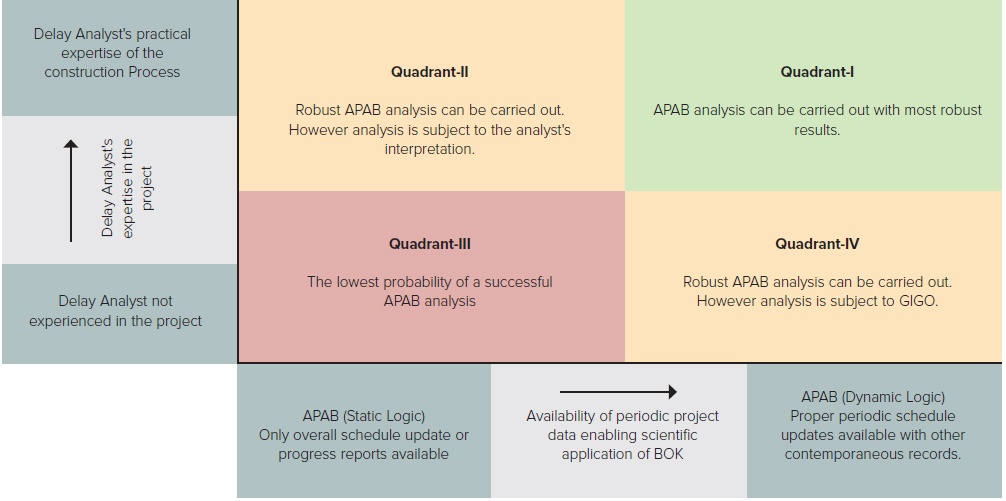

The success of an APAB analysis depends on the delay analyst’s expertise and knowledge of the construction process together with the availability of robust scheduling/programme information and as-built data which enables an interpretive or a combination of an interpretive/systematic application of a recognised BOK. Accordingly, an APAB analysis can be performed effectively using a variety of approaches. Figure 1 sets out the range of approaches to the broad methodology of APAB analysis. Some require only expertise (purely discretionary analysis) (refer to the yellow area, Quadrant-II in Figure 1), and some are more mechanical or systematic in nature and rely on the comparison of as built data with short term CPM projections (refer to the yellow area, Quadrant-IV in Figure 1). Systematic approaches rely on the quality of scheduling/programming data. A purely systematic application is mechanical and may not always result in a successful analysis i.e. Garbage In, Garbage Out (GIGO). A combination of expertise coupled with a systematic analysis will likely yield the most reliable APAB analysis (refer to the green area, Quadrant-I in Figure 1).

Figure 1: Strength/Weakness matrix of APAB analysis

Whatever the case may be, the primary aim for all the methods used in APAB analysis is the determination of an accurate as-built critical path. The authors propose that the most accurate implementation exists when the analyst has significant expertise in the construction process and the project documentation is comprehensive lending itself to a disciplined and “scientific” application of the prevailing BOK, and correspondingly yields the poorest results in the converse scenario.

As mentioned earlier in this article an APAB approach is an observational technique carried out retrospectively. The Forensic Schedule Analysis Recommended Practice No. 29R-03 (FSARP)8 under Method Implementation Protocol’s (MIP’s) 3.1 to 3.5 further classifies the observational methods into static logic and dynamic logic. The processes range from static logic (MIP’s 3.1 and 3.2) being unscientific to dynamic logic (MIP’s 3.3, 3.4 and 3.5) being more scientific. Accordingly, the APAB analysis can be broadly classified as:

- APAB Analysis (Static Logic)

- APAB Analysis (Dynamic Logic)

The APAB Analysis (Static Logic) is an observational method carried out retrospectively that compares the as-planned schedule/programme with an as-built schedule/programme. The comparison can be made using either a gross approach where the analysis is performed on the entire project or can be performed in periodic segments. Identifying the as-built critical path using this methodology requires detailed knowledge of the project process. In its simplest application, the method can be implemented using a simple graphic comparison of the as-planned to the as-built schedule/programme or an observational study of start and finish dates of various activities. The “retrospective longest path analysis” methodology in SCL Protocol (2nd Edition)9 can be categorized under APAB (Static Logic) where the longest continuous path (as-built critical path) is traced by the delay analyst. The validity of the as-built critical path depends on the expertise of the analyst.

The APAB Analysis (Dynamic Logic) is also an observational method carried out retrospectively. The difference from the static logic approach is that contemporaneous progress updates are used to identify the as-built critical path in this method. The analyst identifies critical delays periodically in order to develop the overall as-built critical path. The range of application of this methodology varies based on the availability and reliability of contemporaneous programme updates. To establish the as-built critical path using programme updates, the SCL Protocol (2nd Edition)10 provides two forms of ‘windows’ analysis – “time slice analysis” and “as-planned versus as-built windows”. The difference between the two forms is that the latter is less reliant on the programming software and is used when there is concern over the validity of the planned programme and/or contemporaneous programme updates. Accordingly, the latter requires the analyst to have a higher level of expertise.

APAB (Dynamic logic) is observational analysis and different from ‘dynamic analysis’ since it does not involve the insertion or extraction of delays, instead it is based on observing the behaviour of the network from update to update.

From the above explanation it can be inferred that the APAB methodology which is identified as one of the basic methodologies in SCL Protocol (October 2002) has been further detailed as a “retrospective longest path analysis”, “time slice analysis” and “as-planned versus as-built windows” in SCL Protocol (2nd Edition). This again shows the range of available approaches to the broad methodology of APAB analysis.

Case Study

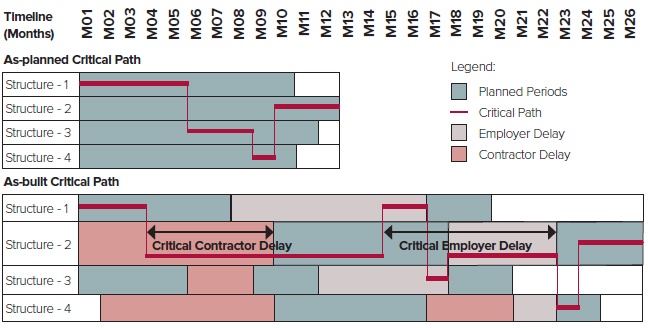

The following case study analyses a design and build project in the Middle-East which illustrates the practical and common-sense approach that can be applied in an APAB analysis. The project involved the construction of four structures. The critical path for the project ran through sections of structures 1, 3, 4 and 2 in a sequential manner (refer to Figure 2). There was only one completion milestone for the project.

Figure 2: Case Study: as-planned Critical Path and as-built Critical Path (High level)

The contractor did not update the approved programme regularly and the available programme updates were unreliable. However, the contractor submitted weekly and monthly progress reports which contained as-built progress quantities. Accordingly, the only practicable way forward was to compare the actual quantities against the planned quantities to assess the delays. For this purpose, monthly progress quantities were summarised and an as-built schedule/programme developed.

As discussed in the previous section of this article, this example illustrates a situation where reliable progress updates are not available and that a systematic analysis using the BOK was not possible. The expertise and experience of the delay analyst in the construction process was instrumental in this case. In the matrix provided in Figure 1 this case is an example to be placed in Quadrant-II.

The monthly actual progress quantities were plotted graphically against the planned quantities to develop an as-built critical path for each of the structures. Further analysis of the as-built critical paths of the four structures established the as-built critical path through the project. Expert review of the executed quantities against the required quantities in the planned sequence of works and the delaying events helped in identifying the

as-built sequence of works. As-built data shows that Structures 1 and 3 progressed well initially; whereas Structure-2, which was near critical in the planned programme was delayed. This resulted in the critical path moving from Structure-1 to Structure-2. A high-level summary of the as-built critical path against the as-planned critical path is illustrated in Figure 2.

This study illustrated the capacity of APAB analysis in non-programme-based delay analysis. APAB analysis gives the analyst the flexibility to subjectively interpret results through expertise and experience. In the absence of regular programme updates, a realistic evaluation was still possible using the APAB method. However, the implementation of the methodology was time-consuming and required significant effort and expertise.

The results of APAB analysis is sometimes counter-argued as being subjective, as it depends on interpretation from the analyst. In the above example, the expert identified that the critical delays moved to Structure-2 as it was near critical in the planned schedule/programme. The critical path determined by the expert was disputed by the opposing expert, who also had significant construction process expertise. The opposing expert derived a different as-built critical path based on the same set of facts. This illustrates that a purely interpretive approach can lead to different conclusions, which then becomes unhelpful to the court/tribunal.

Conclusion

In conclusion, the APAB method of analysing delays is pragmatic and if competently implemented in a purely subjective capacity or a combination of a subjective and mechanical capacity satisfies the four criteria set out in the case of Kennedy v Cordia and can assist the court/tribunal. However, the expert’s subjective interpretation of the as-built critical path should be rigorously tested under cross examination even if the analysis is founded on verified facts.

1 Kennedy v Cordia is a Scottish case where Expert Witnesses were referred to as Skilled Witnesses.

2 “Society of Construction Law (SCL) Delay and Disruption Protocol October 2002” (p46-p48)

3 Keane P J and Caletka A F, “Delay analysis in Construction Contracts” (1st edition, Blackwell Publishing Ltd, Oxford 2008) p124

4 “AACE International Recommended Practice No. 29R-03, FORENSIC SCHEDULE ANALYSIS, (25 April 2011)” (p12-p14)

5 “Society of Construction Law (SCL) Delay and Disruption Protocol 2nd Edition February 2017” (p62) defines Critical Path Method (CPM) as “The methodology or management technique that, through the use of calculation rules (usually automatically carried out by programming software), determines the critical path and calculates float.”

6 “Society of Construction Law (SCL) Delay and Disruption Protocol 2nd Edition February 2017” (p62)

7 “AACE International Recommended Practice No. 29R-03, FORENSIC SCHEDULE ANALYSIS, (25 April 2011)” (p114)

8 “AACE International Recommended Practice No. 29R-03, FORENSIC SCHEDULE ANALYSIS, (25 April 2011)” (p12-p14)

9 “Society of Construction Law (SCL) Delay and Disruption Protocol 2nd Edition February 2017” (p34-p37)

10 “Society of Construction Law (SCL) Delay and Disruption Protocol 2nd Edition February 2017” (p34-p37)