After burn

Jeremy Ingham, one of our technical experts summarises how fire damaged buildings can be assessed to allow repair rather than demolition.

Fire-damaged commercial and public buildings are often capable of being repaired rather than being replaced. The option of repair rather than replacement is often preferred by owners and their insurers as it can provide substantial savings in expenditure and permit earlier reoccupation. The decision to repair depends not only on the technical feasibility, but also on factors such as aesthetic appearance and the effect on service life and maintenance of the structure. A fundamental part of understanding the technical feasibility of repair is to engage technical experts to undertake an engineering assessment of the damaged structure.

Commercial fire claims can involve a wide variety of building types including offices, schools, warehouses, residential buildings, and power stations. Other scenarios involve civil engineering structures for example, vehicle fires in car parks, tunnels or underneath bridges. Fires can also occur during construction, when combustible materials present at the construction site such as concrete formwork and scaffolding boards may provide a source of fuel (Fig.1). In the aftermath of a fire the focus is on immediate measures to ensure the safety and security of the building or structure. Once these immediate concerns have been dealt with, the requirements are generally for an immediate and thorough damage assessment to be carried out.

Fig.1 – The interior of a building that was fire damaged during construction

Assessment of fire damaged structures

In summary, the assessment, design and repair of fire-damaged structures consists of the following stages:

- Preliminary inspection

- General assessment of damage

- Materials testing and detailed damage assessment

- Design of repairs to structural elements

- Implementation of structural repairs

The aftermath of a serious fire can appear to be a scene of apparent devastation to the untrained eye, but this can be misleading. Methodical assessment by technical experts is required to correctly determine the degree of damage and condition of the structure. Guidance for assessment of the effects of fire can be found in the Institution of Structural Engineers publication ‘Appraisal of Existing Structures’1. There are two possible assessment approaches as listed below. These can be used separately, or they can be combined, depending on the nature of the fire and of the structure as follows:

Approach A: Test the fire-damaged material to directly assess the condition

- Visual inspection and hammer soundings

- Non-destructive testing

- Sampling and subsequent laboratory testing

Approach B: Indirect estimation of fire-damaged elements to deduce temperature profiles and calculate residual strength

- Evaluation of fire severity (debris inspection, numerical evaluation methods, etc)

- Determination of temperature profiles (by applying numerical methods or simpler calculation techniques)

- Assessment of residual strength

The deliverable of an assessment is usually a damage classification document, which can then be used in the selection of appropriate repair techniques. The assessment should provide enough information to prepare detailed drawings with instructions on how to repair the structure.

An assessment programme will consist of on-site and off-site work. Initially, all available data relating to cause, fuel source, progression/duration of the fire should be sought off-site, including information regarding how the fire was extinguished. Prior to undertaking on-site inspection, the investigator must be satisfied that the structure is safe to enter. Temporary props may be required to secure individual members and stabilise the structure. The primary on-site investigation technique is visual inspection, which records such features as collapse, distortion, deflections, degree of damage to materials and smoke damage. A site-specific classification scheme for the damage would normally be devised.

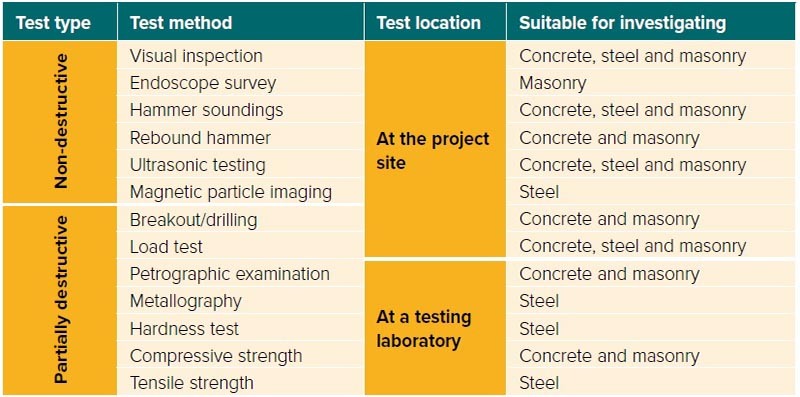

Various complementary non-destructive testing (NDT) techniques can be used to assess material strength in-situ2. For concrete and masonry these include Schmidt (rebound) hammer, ultrasonic pulse velocity, penetration resistance test and the drilling resistance test. For steel, indentation hardness tests can be used to identify damaged members. In addition, it may be appropriate to remove samples of damaged material (and undamaged references) for laboratory testing. Concrete and masonry samples are typically obtained by diamond drilling of cores, while samples of steel are cut out using an angle grinder or saw. Table 1 provides a summary of the testing options.

Table 1 – Test method options for assessment of fire-damaged structures.

As an alternative or addition to inspection and testing, predictive fire engineering tools, such as empirical equations or computer modelling used in design, can be used to assess the fire severity in the structure. These predictions are based on the fire load in the building, ventilation conditions, compartment size and shape and properties of wall linings.

Based on the findings of the fire damage assessment, decisions regarding any reduced load-bearing capacity to the structure can be made. Instrumented load tests can be used to confirm whether load capacity has been impaired. Load tests can also be used to investigate the effectiveness of repairs in structural terms.

Concrete

Concrete is a poor conductor of heat and incombustible; it offers good fire resistance. However, heating will eventually compromise the load-bearing capacity of concrete elements. In practice, the worst damage is usually confined to the outer surface and even severe fires seldom cause total structural collapse. Experience has shown that following detailed appraisal, fire-damaged concrete structures can usually be reinstated using conventional concrete repair techniques (Fig.2), sometimes combined with replacement of selected structural elements.

Fig.2 – Repair of a fire-damaged reinforced concrete using sprayed concrete

Guidance for the assessment of fire-damaged concrete structures is given in Concrete Society Technical Report 683. The strength of concrete after a fire varies depending on temperature attained, the heating duration, the concrete mix and the applied loading during heating. For temperatures up to 300°C, the strength of concrete is not significantly reduced, while for temperatures greater than 500°C it can be reduced to only a small fraction of its original value. 300°C is normally taken to be the critical temperature above which, concrete is deemed to have been significantly damaged.

Masonry

Masonry structures typically offer good fire resistance as (like concrete) materials such as stone, brick, terracotta and mortar are incombustible and have low thermal conductivity. Nevertheless, masonry structures can still be seriously affected by fires. The types of masonry structures most likely to be subjected to fire include domestic and public buildings and notably, may include buildings of historic and cultural value. In buildings the damage tends to be concentrated around window openings and doorways but may also affect structural masonry. At 600-800°C the strength of most natural stones and masonry mortars is seriously affected and if thermal shock occurs the stone can disintegrate. Cracking can also be caused by quenching masonry heated by fire with fire-fighting water.

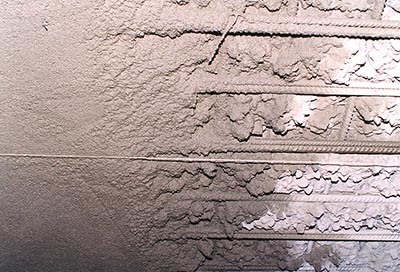

Clay bricks can withstand temperatures in the region of 1000°C or more without damage, but under very severe and prolonged heating the surface of the brick may fuse. Spalling (where the surface falls away) may occur with some types of brick (Fig.3). At low temperatures (250-300°C) damage is usually restricted to colour changes, such as reddening of iron-bearing stones and mortars. Although not structurally significant, as the colour change is non-reversible it may be significant for aesthetic reasons, especially in the case of historic buildings.

Fig.3 – Spalling of a brick masonry wall caused by fire

Steelwork

Steel has a high thermal conductivity and unprotected steelwork will rapidly increase in temperature during a fire. For this reason, structural steelwork is often protected by insulation (passive fire protection) and the adequacy of this will play an important part in the outcome of a fire. The situation is different for steel reinforcement bars embedded in concrete as the concrete that covers them provides protection, until it has either spalled away in the fire or heat is eventually transmitted through the concrete.

Significant loss of strength and stiffness of steel may occur while the steel is at high temperature. However, recovery of strength after cooling is generally complete for temperatures up to 450°C for cold worked steel and 600°C for hot rolled steel. Above these temperatures, there will be a permanent loss in strength. In addition to reduction in strength the effects of heating may include distortion (Fig.4), axial shortening of columns, over-stressing of bolts, connections and welds.

Fig.4 – Fire-damaged steelwork showing distortion

Heating of reinforcing steel in concrete eventually causes buckling and residual defections of the structural element. The effect of high temperature is more critical on prestressing steel than on reinforcing steel. At temperatures of 200-400°C, steel prestressing tendons show considerable loss of strength (>50% loss at about 400°C). To assess fire damage of steel reinforcement in concrete, the visual assessment may be complemented by in-situ strength testing using portable hardness testers. Furthermore, samples may be taken for laboratory testing with the results being compared with the relevant standard for the grade of steel concerned.

- The Institution of Structural Engineers. 2010. Appraisal of existing structures. Third edition.

- Ingham, J. P. 2009. Forensic engineering of fire-damaged structures. Proceedings of the Institution of Civil Engineers, Civil Engineering, Vol 162, Special Issue – Forensic Engineering, 12-17.

- The Concrete Society. 2008. Assessment, design and repair of fire-damaged concrete structures. Technical Report 68. The Concrete Society, Camberley, UK.